Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

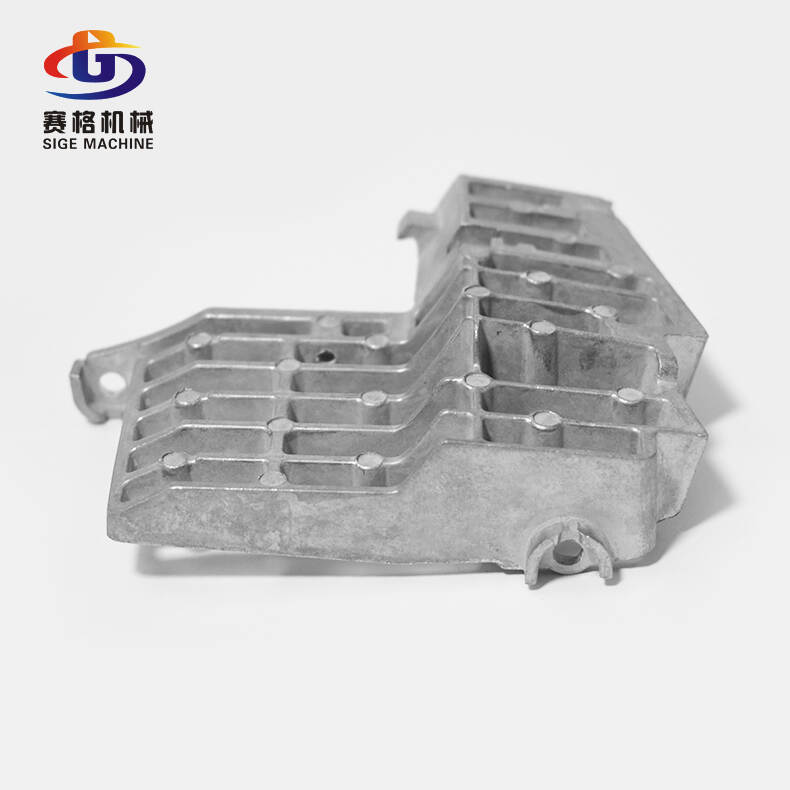

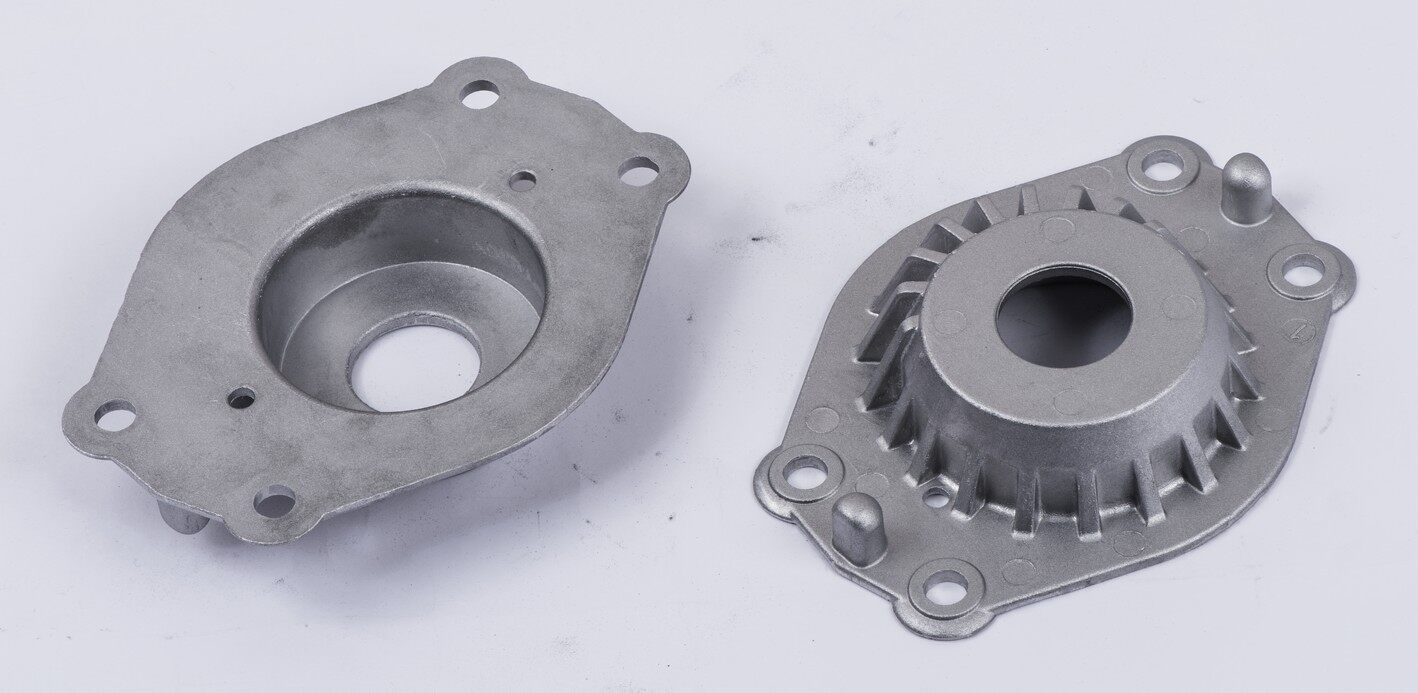

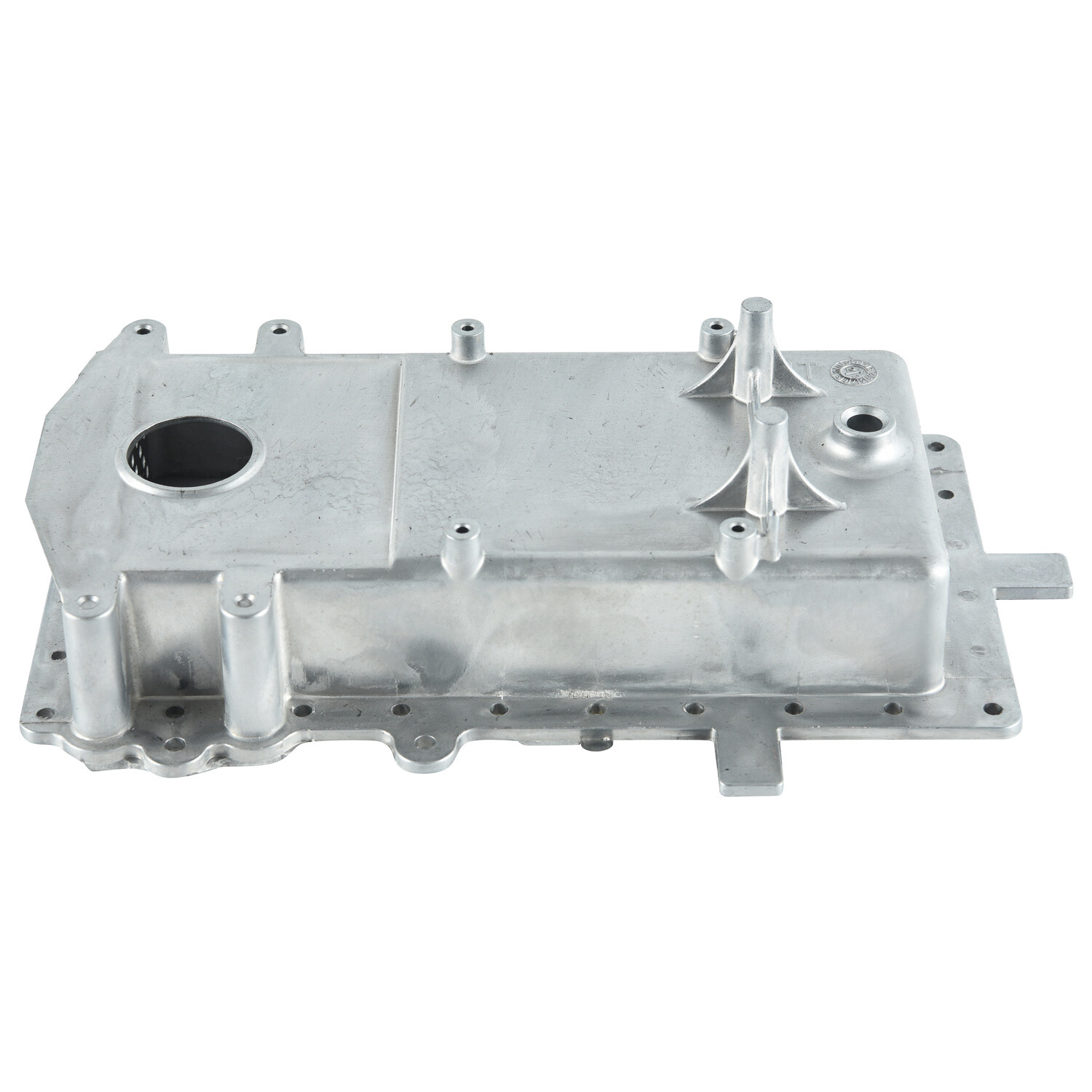

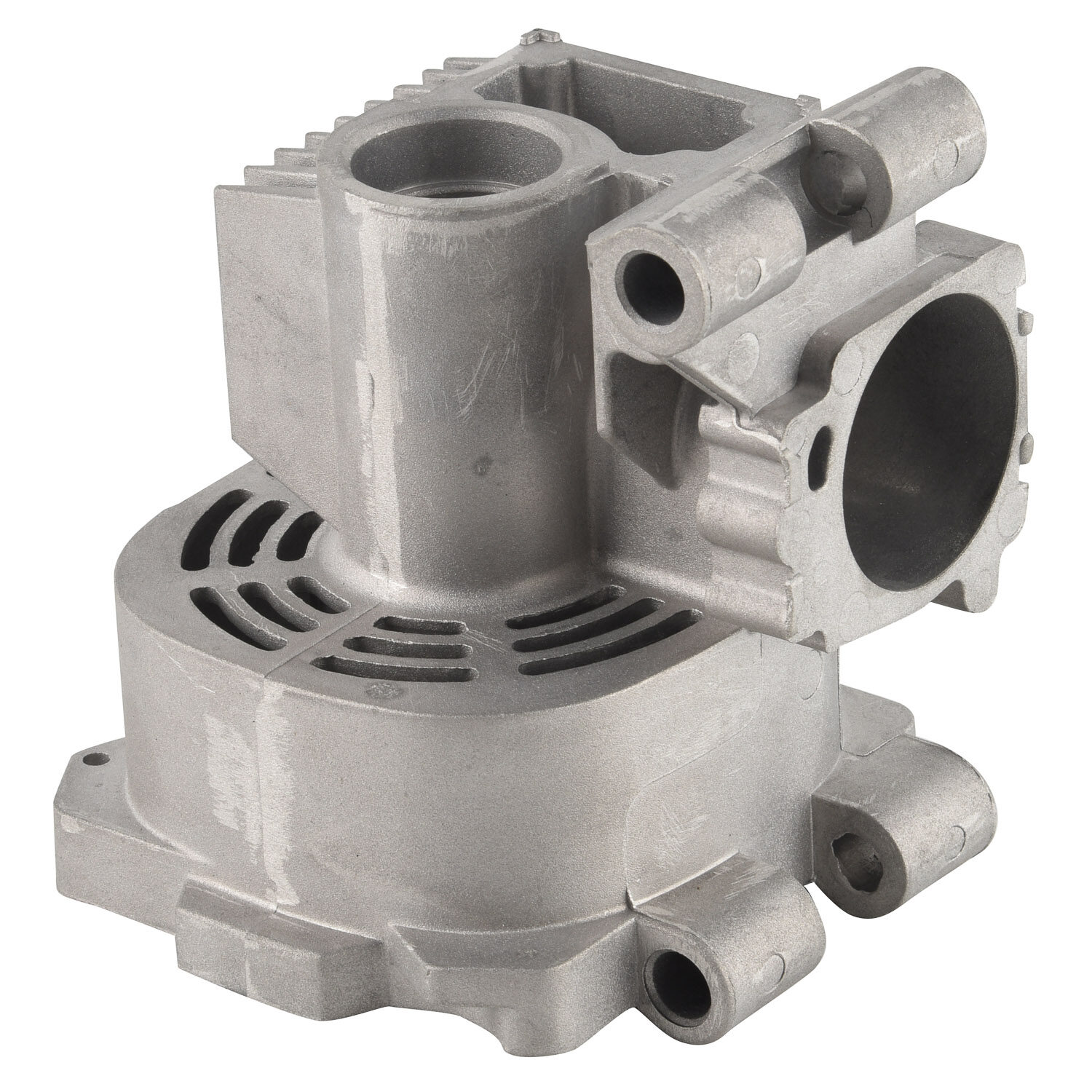

Auto Light Die Casting Heat Sink

-

USD 5.00 ~ USD 8.00/piece

500/ piece (Min. Order)

Heat sink, a fundamental component in thermal management systems, serves a vital role in dissipating heat generated by electronic devices and machinery. Designed to efficiently transfer heat away from sensitive components, Heat sink ensures optimal performance and reliability in various applications. With its ability to regulate temperatures and prevent overheating, Heat Sink plays a crucial role in maintaining the longevity and efficiency of electronic equipment across industries.

Product Description

Customer Question & Answer

2. Own factory production, reasonable prices

3. Good at a die casting light

4. IATF16949:2016 Certificated

5. With the European market since 2010

| Technics & process | Aluminum alloy die casting: 44300,44300/46000/ADC12/A360/A380/Alsi9cu3,etc. Aluminum alloy profile extrusion: 6061 6063 CNC machining and Turning: 6061 6063 Part Weight: From 10g to 15000g Mould manufacture: Part design drawing (prt/fem/igs/stp/dxf/model/x-t/x-b forms)-mould making-sample supplied |

| Equipment | Cold chamber dies casting machine:200T/280T/400T/500T/800T/1250T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Surface Treatment | Trimming, Deburring, Polishing, shot blasting, sandblasting, tumbling, powder coating, anodizing, chrome, zinc, electrophoresis, passivation, chemical coating |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automobile Bicycle and motorcycle Door and windows and furniture Household appliance Gas meter Power tool |

Manufacture Process:

1. Review the part design, drawings, and quality standards from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirming the sample

4. Die casting raw castings

5. Surface treatment: Trimming, Deburring, polishing, cleaning, passivation & power coating, and another requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding, etc

7. Full Inspection

8. Packing

9. Delivery

Service:

1. OEM and ODM.

2. Quotation within 24 hours.

3. Inspection service by SGS or any other inspection assigned by Customer.

4. Shipping service.

5. After service

Why choose us:

1. Our technical know-how and experienced team ensure us being able to offer the service with International standard towards to our customers.

2. Relying on International tooling designing concept and manufacturing, we could build tailor-made tools to satisfy the quality of your product requirement.

3. Equipped uniquely with top-performance die casting machines and CNC machines, give us the possibility to produce high precision products.

4. The strong application technical support towards the customer in the project development phase which different from the other suppliers. Our mission is building long term co-operation with our customers

Heat Sink

Product Description

Heat sink is a passive cooling device typically made of aluminum, copper, or other conductive materials with high thermal conductivity. Its structure consists of a series of fins or ridges that increase the surface area available for heat dissipation. Heat Sink is commonly used in electronic devices such as computers, LED lights, and power amplifiers, as well as industrial machinery and automotive systems.

Product Features

Improved Performance: Heat sink efficiently dissipates heat, maintaining optimal temperatures, and improving electronic device and machinery performance and longevity.

Enhanced Reliability: With robust construction and effective thermal management, the heat sink enhances equipment reliability, reducing the risk of overheating-related failures and downtime.

Energy Efficiency: By preventing heat buildup, it reduces the need for active cooling systems and lowers overall power consumption, promoting energy efficiency.

Cost Savings: It extends component lifespan, reducing maintenance costs and minimizing the risk of premature equipment failure, leading to cost savings.

Product Advantages

Maximized Thermal Conductivity for Efficient Heat Dissipation: Heat sink is engineered to swiftly transfer heat from heat-generating components to the surrounding environment. Its design maximizes thermal conductivity, ensuring rapid heat dissipation and precise temperature regulation.

Increased Surface Area for Improved Heat Dissipation: Featuring fins or ridges, heat sink enhances its surface area for efficient heat dissipation. This design improvement significantly improves cooling efficiency, even in confined spaces.

Robust Construction for Long-lasting Durability and Reliability: Constructed from premium materials like aluminum or copper, heat sink offers exceptional durability and resistance to corrosion and thermal fatigue. Its sturdy build withstands harsh conditions, ensuring long-term reliability without compromising performance.

Versatile Applications Across Diverse Industries and Environments: Heat sink finds applications across industries such as electronics, telecommunications, automotive, aerospace, and industrial automation. Its versatility makes it indispensable for managing heat in various environments, ensuring optimal performance and reliability in diverse settings.