Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Discover SEIPO's Core Competencies in Custom Die Casting

Discover SEIPO's Core Competencies in Custom Die Casting

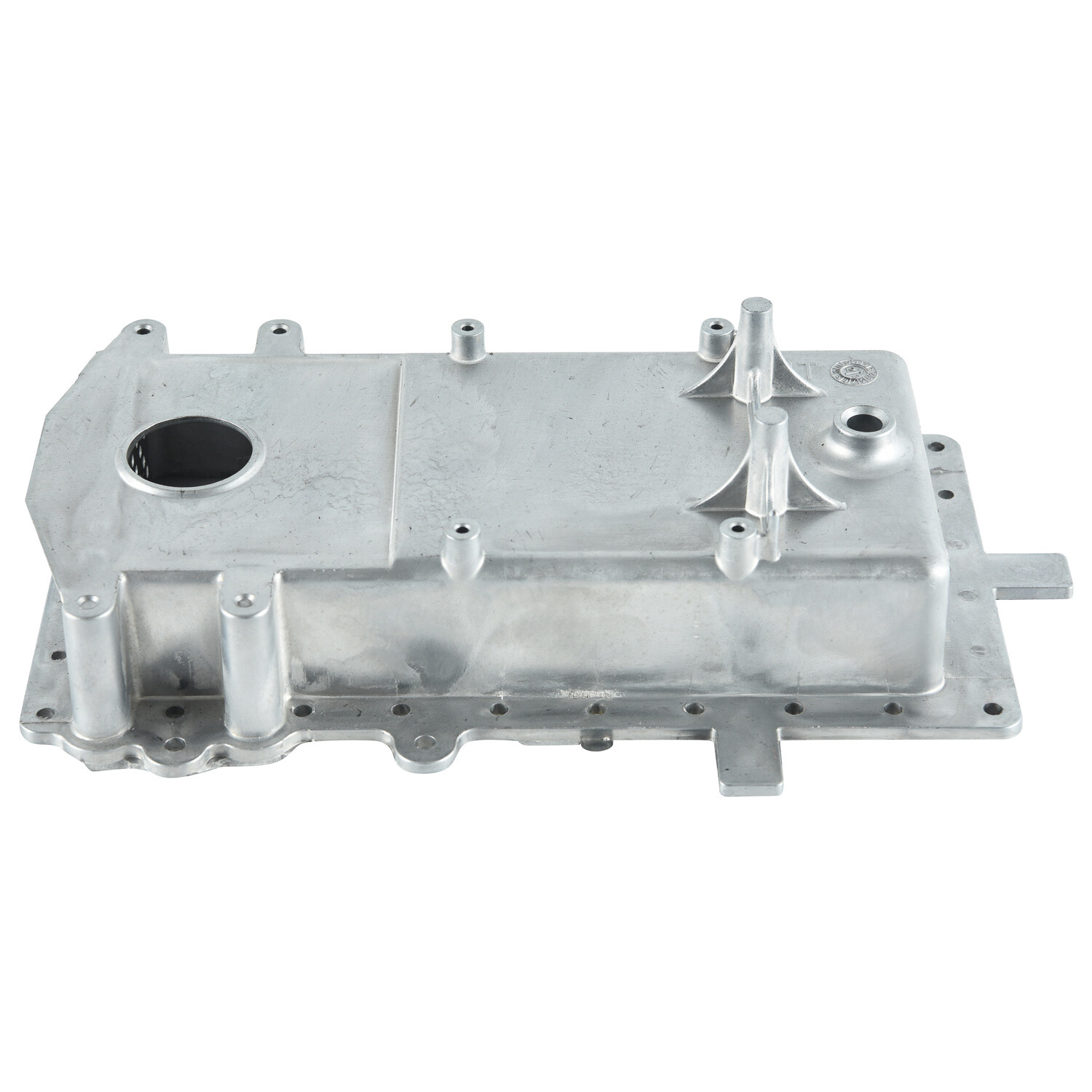

In the ever-evolving world of manufacturing, the demand for precision, efficiency, and sustainability is at an all-time high. At Ningbo Seipo Machinery Co., Ltd., we understand that meeting these demands requires more than just advanced technology; it requires a commitment to excellence. Our core competencies in custom die casting are designed to meet the diverse needs of our clients, providing solutions that transform complex designs into high-quality metal parts with ease and precision.

Seamless Integration of Technology and Expertise

At SEIPO, we pride ourselves on merging cutting-edge technology with deep industry expertise to become your end-to-end manufacturing partner. Our ability to deliver engineered die casting solutions that are faster, smarter, and uncompromisingly precise sets us apart in the industry.

Expert Tooling Design & Fabrication

Our mold engineers utilize advanced CAD/CAE simulation tools to optimize gating, cooling, and structural integrity, resulting in high-performance dies with extended lifespans. This meticulous attention to detail ensures reduced cycle times and flawless part consistency, even for the most intricate geometries.

Multi-Material Capabilities

SEIPO offers a diverse range of material capabilities to meet the specific needs of different industries:

- Aluminum Die Casting: Lightweight yet high-strength options like ADC12, A380, and A360, ideal for automotive, telecom, and electronics applications.

- Zinc Die Casting: Provides superior fluidity for thin walls and a great surface finish, perfect for connectors, hardware, and decorative components.

- Magnesium Die Casting (On-demand): Offers ultimate weight savings, suitable for aerospace and premium consumer goods.

Precision Production

Equipped with advanced LK die casting machines (280T-2500T), we ensure tight tolerances of ±0.05mm and controlled porosity, supporting capabilities from rapid prototyping to high-volume runs.

Comprehensive Post-Processing

Our services don't stop at casting. We offer deburring, CNC machining, surface finishing (including anodizing, plating, and powder coating), assembly, and rigorous QA/QC processes including CMM, X-ray, and spectrometry.

Your Competitive Edge with SEIPO

By choosing SEIPO, you gain access to:

- Quality Certified: IATF 16949 & ISO 9001 compliant processes

- Speed-to-Market: Agile prototyping and scalable production

- Cost Efficiency: Optimized tooling and lean manufacturing practices

- Full Turnkey Service: From DFM analysis to finished parts

- Global Support: Engineering collaboration across time zones

Industries We Serve

SEIPO’s die casting solutions are pivotal across various industries including automotive (EV components, housings), 5G/telecom (heat sinks, enclosures), industrial machinery, consumer electronics, lighting, and non-implantable medical devices.

Experience the SEIPO Advantage

Partner with SEIPO to benefit from high-integrity parts, 30% faster lead times, and a 15% cost reduction compared to industry averages.

Ready to elevate your project? Contact us today for a free DFM analysis and quote.

📞 +86 1300 377 4020 | ✉️ harry@seipo.cn

📥 Request a Free DFM Analysis & Quote