Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

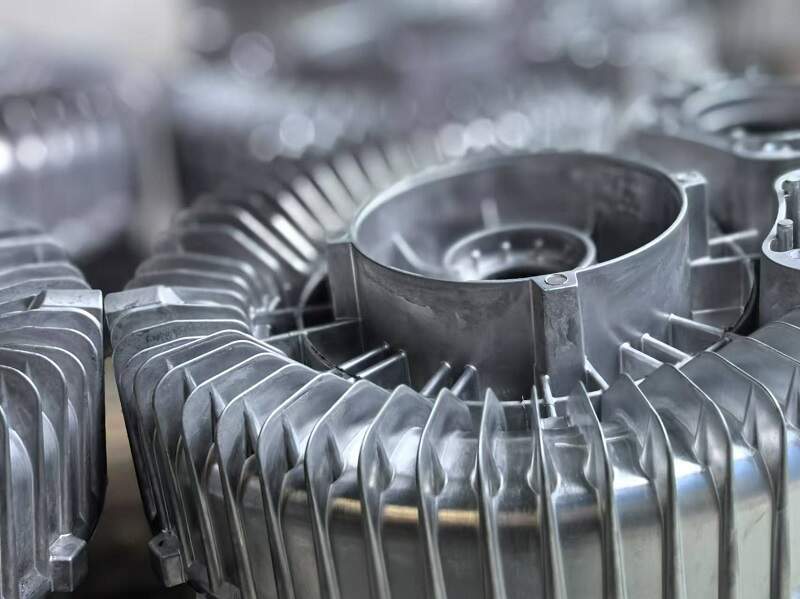

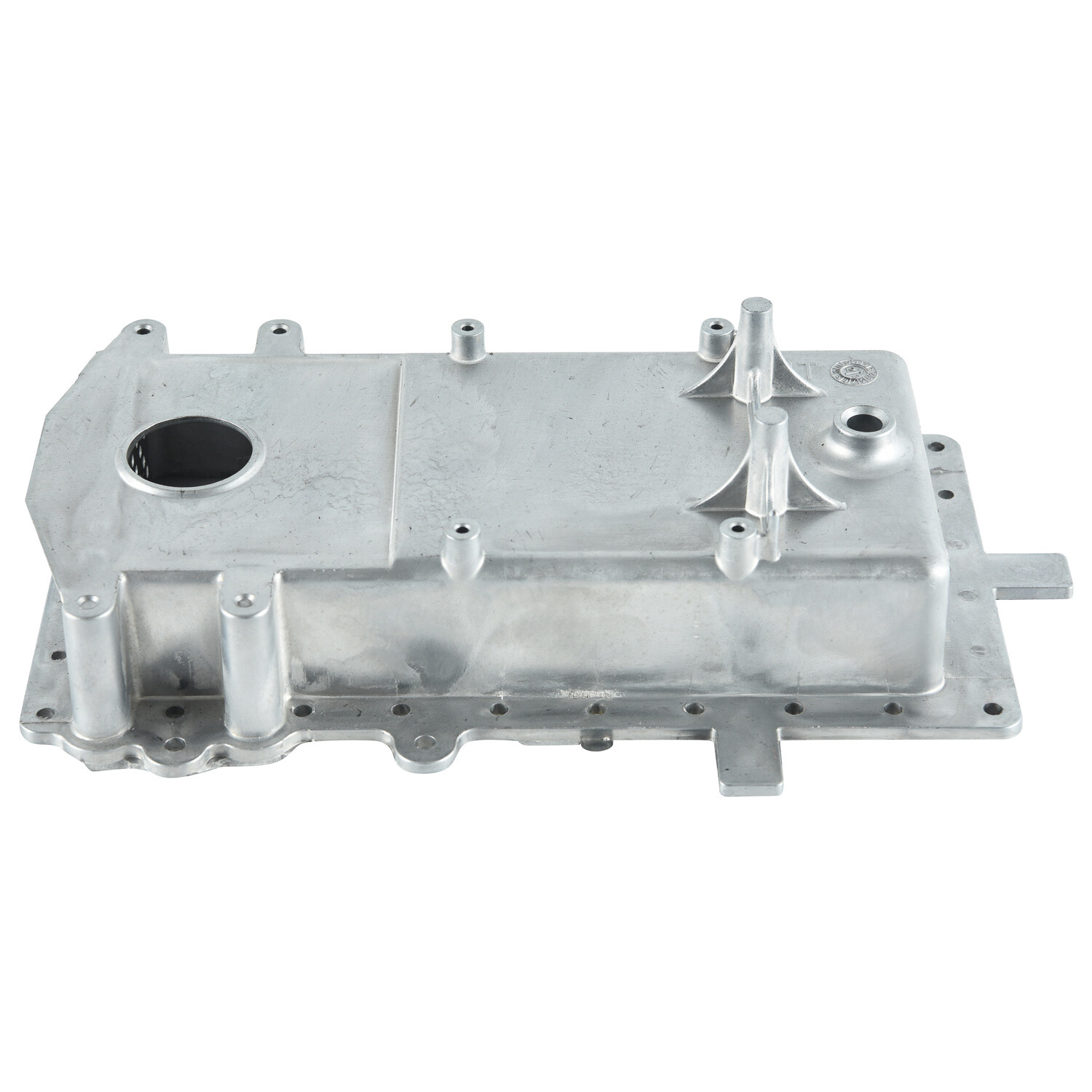

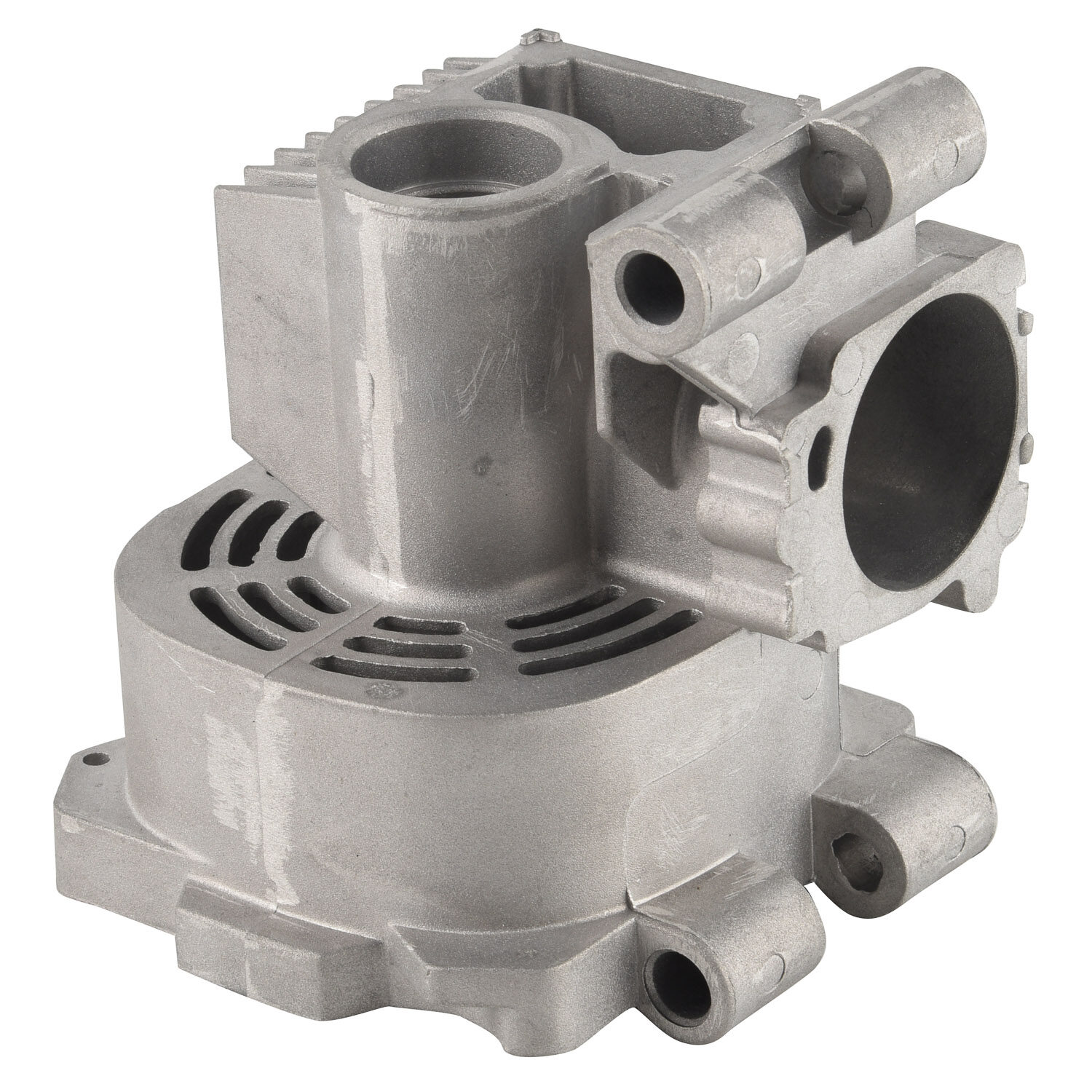

custom die casting services

FAQs about Custom Die Casting Services

Introduction

Custom die casting services involve the manufacturing process of creating metal parts by injecting molten metal into a steel mold, known as a die. This process is commonly used in various industries such as automotive, aerospace, and electronics. If you have questions about custom die casting services, this FAQ article is here to provide you with answers.

Common Questions

Question 1: What is the advantage of custom die casting services?

Answer 1: Custom die casting offers high precision and complex shapes with excellent surface finishes. It is a cost-effective method for mass production of metal parts with consistent quality.

Question 2: What materials can be used in custom die casting?

Answer 2: Common materials for custom die casting include aluminum, zinc, and magnesium. Each material has its own unique properties and benefits for different applications.

Question 3: How long does the custom die casting process take?

Answer 3: The duration of the custom die casting process depends on the complexity of the part and the quantity being produced. Typically, it can range from a few weeks to a couple of months.

Question 4: What are the quality control measures in custom die casting?

Answer 4: Quality control in custom die casting involves inspecting the parts for defects, ensuring dimensional accuracy, and conducting material testing. Advanced technologies like X-ray inspection and computer simulations are also used to maintain quality standards.

Question 5: Can custom die casting services be used for prototyping?

Answer 5: Yes, custom die casting can be used for prototyping to test the design and functionality of the part before full-scale production. It allows for quick iterations and modifications to the design if needed.

Conclusion

Custom die casting services offer a versatile and efficient solution for manufacturing metal parts. By understanding the process and benefits of custom die casting, you can make informed decisions for your production needs. If you have more questions or need further information, feel free to contact us for assistance.

Seipo: Engineered Excellence in Custom Die Casting Solutions

In a world where precision, durability, and complex geometries define competitive advantage, Seipo stands as your trusted partner for high-performance custom die casting. We transform innovative designs into robust, high-volume metal components that power industries worldwide.

Beyond Casting: Your End-to-End Precision Manufacturing Partner

Seipo is more than a foundry; we are an extension of your engineering team. Leveraging decades of expertise and cutting-edge technology, we specialize in producing intricate, near-net-shape metal parts with exceptional dimensional accuracy and repeatability. Our core mission: to deliver quality, efficiency, and scalability for your most demanding applications.

Why Global Leaders Choose Seipo:

-

Unmatched Precision & Consistency:

-

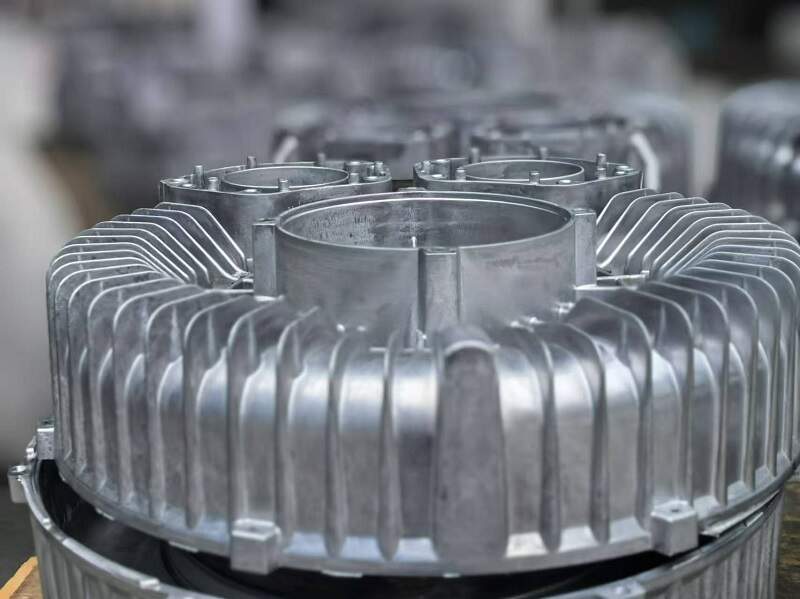

Advanced high-pressure & low-pressure die casting processes.

-

Rigorous process control ensuring micron-level tolerances (±0.05mm achievable).

-

State-of-the-art CNC machining centers for critical finishing.

-

Comprehensive in-house inspection (CMM, X-ray, 3D scanning) guaranteeing every part meets spec.

-

-

Material Science Expertise:

-

Mastery of aluminum, zinc, and magnesium alloys.

-

Guidance on optimal material selection for strength-to-weight ratio, corrosion resistance, thermal/electrical conductivity, and cost-efficiency.

-

Dedicated metallurgical support for specialized requirements.

-

-

Integrated Value Chain:

-

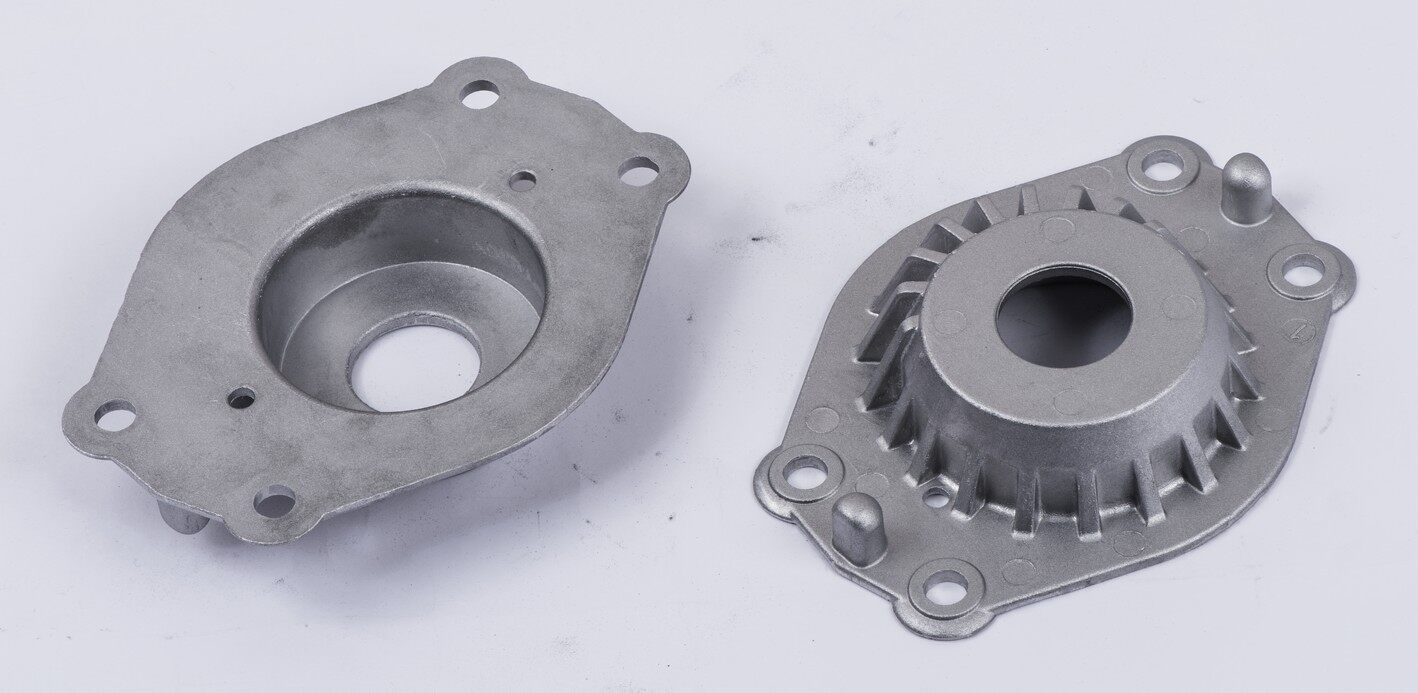

Design for Manufacturability (DFM): Proactive engineering collaboration to optimize part design, reduce costs, and enhance quality from concept.

-

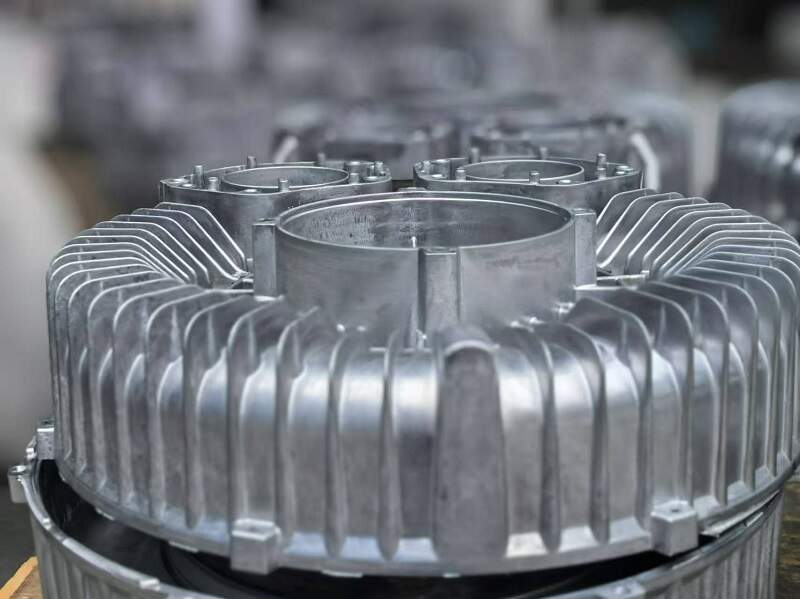

High-Performance Tooling: Robust, precision tool design and fabrication using premium steels for longevity and high-volume production.

-

Seamless Secondary Operations: Full suite of finishing services – precision machining, surface treatments (anodizing, plating, painting, powder coating), heat treatment, assembly, and packaging.

-

Supply Chain Simplification: Single-source responsibility from raw material to finished part.

-

-

Scalable Solutions for Every Stage:

-

Rapid Prototyping: Accelerate development with quick-turn die cast samples.

-

Low-to-Medium Volume: Flexible production runs without sacrificing quality.

-

High-Volume Manufacturing: Optimized processes and capacity for sustained, cost-effective mass production.

-

-

Industry-Leading Quality Commitment:

-

Stringent quality management systems ([Mention specific certifications if applicable, e.g., ISO 9001:2015, IATF 16949]).

-

Data-driven process monitoring and continuous improvement culture.

-

Traceability and documentation for critical applications.

-

Powering Innovation Across Industries:

Seipo components are the hidden strength within:

-

Automotive & EV: Lightweight structural parts, e-motor housings, battery components, brackets.

-

Electronics & 5G: EMI/RFI shielding, heat sinks, connectors, rugged enclosures.

-

Industrial Machinery: Durable pump housings, valves, hydraulic components, gears.

-

Consumer Durables: High-quality appliance parts, power tool components, sporting goods.

-

Lighting: Efficient thermal management solutions, fixture housings.

-

Renewable Energy: Robust components for solar trackers, wind turbines, power converters.

-

Medical & Aerospace: Precision components meeting stringent regulatory demands [Specify if certified].

Partner with Seipo for Competitive Advantage:

Choosing Seipo means investing in:

-

Reduced Total Cost: Optimized designs, efficient processes, and minimized waste.

-

Faster Time-to-Market: Streamlined workflow from DFM to delivery.

-

Enhanced Product Performance: Superior component integrity and reliability.

-

Uncompromising Quality & On-Time Delivery: Predictability you can build your supply chain on.

-

A True Collaborative Partnership: Dedicated engineers focused on your success.

Ready to Elevate Your Manufacturing?

Stop searching for standard solutions. Engage Seipo’s expertise to unlock the full potential of custom die casting for your next project.

Contact Seipo today for a consultation and quote. Let's engineer success together.

➤ Explore Our Capabilities:www.diecasting-china.com

➤ Speak to an Expert: +86 1300 377 4020

➤ Email Us: harry@seipo.cn

Seipo: Precision Cast. Perfectly Engineered. Delivered.